怎么檢查燃氣發(fā)電機組的進氣系統(tǒng)?

燃氣發(fā)電機組安全操作規(guī)程

Safety Operation Regulations for Gas Generator Sets

一、發(fā)電機組啟動前的準備

1、 Preparation before starting the generator set

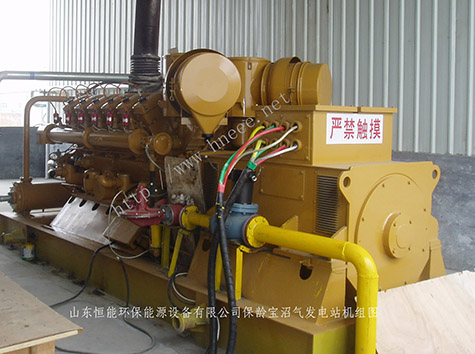

1、外觀狀況檢查發(fā)電機組所有零部件齊全完整,各管路連接正確、密封有效,底盤及各部件聯(lián)結牢固,無松動現(xiàn)象。

1. Inspect the appearance of the generator set to ensure that all components are complete and intact, all pipelines are connected correctly and sealed effectively, and the chassis and components are firmly connected without any looseness.

2、進氣系統(tǒng)檢查發(fā)電機組進氣口前的燃氣管道、燃氣處理設備、安全裝置聯(lián)接可靠,無泄漏;打開燃氣閥門,檢查機組燃氣管路應無漏氣。

2. Check the gas pipeline, gas treatment equipment, and safety devices in front of the intake system of the generator set for reliable connection and no leakage; Open the gas valve and check that there is no air leakage in the gas pipeline of the unit.

3、潤滑系統(tǒng)檢查向油底殼內(nèi)加注合格、清潔的機油,機油液面高度應接近油標尺的上刻度線位置。

3. Check the lubrication system and add qualified and clean engine oil to the oil pan. The oil level should be close to the upper mark of the dipstick.

4、冷卻系統(tǒng)檢查(1)檢查機組內(nèi)循環(huán)冷卻水是否清潔,并符合規(guī)定要求:向高架水箱內(nèi)加注清潔的軟化水,水面高度到合適位置。

4. Cooling system inspection (1) Check whether the circulating cooling water inside the unit is clean and meets the specified requirements: add clean softened water to the elevated water tank, and raise the water level to the appropriate position.

(2)檢查機組外循環(huán)冷卻水池水位、水質(zhì)。

(2) Check the water level and quality of the external circulating cooling water tank of the unit.

(3)環(huán)境溫度低于5C時,應將內(nèi)循環(huán)冷卻水和潤滑油預熱到20C以上。

(3) When the ambient temperature is below 5C, the internal circulating cooling water and lubricating oil should be preheated to above 20C.

5、電氣系統(tǒng)檢查(1)檢查各處連接導線是否牢固,電氣回路的對地以及回路之間的絕緣電阻是否達到規(guī)定值。(測量過程中,機組的電氣部分、半導體元件、電容器等元件的連接應全部斷開(測量結果應不低于2MQ)。蓄電池的接線應牢固可靠,接線應首先將蓄電池的正極接入啟動繼電器下接線柱上;然后再將負極接入機器底盤上并將接線處的漆銹清除干凈。

5. Electrical system inspection (1) Check whether the connecting wires at all locations are firm, whether the ground resistance of the electrical circuit and the insulation resistance between circuits meet the specified values. During the measurement process, all connections of the electrical parts, semiconductor components, capacitors, and other components of the unit should be disconnected (the measurement result should not be less than 2MQ). The wiring of the battery should be firm and reliable. The positive terminal of the battery should be connected to the lower terminal of the starting relay first; Then connect the negative electrode to the machine chassis and clean the paint rust at the wiring.

(2)機組并網(wǎng)(并車)運行前進行相序檢查,確保發(fā)電機組的相序與電網(wǎng)的相序相同,或機組與機組間相序一致。初次投入運行的機組應測量各個電氣回路的絕緣電阻:測量發(fā)電機繞組絕緣電阻時應先將“AVR”板上X1插頭拆下,其絕緣電阻應>2M2,已運行的機組絕緣電阻應>0.5MQ。檢查控制屏上的報警指示及聲響動作正常。合上蓄電池開關,按動試報警按鈕,各指示燈應同時閃爍,電鈴或電喇叭發(fā)出報警聲響,按動消音按鈕,聲響終止:按動報警解除按鈕,各指示燈熄滅。

(2) Before the unit is connected to the grid (parallel operation), a phase sequence check should be conducted to ensure that the phase sequence of the generator set is the same as that of the power grid, or that the phase sequence between units is consistent. The insulation resistance of each electrical circuit should be measured for the first operation of the unit: when measuring the insulation resistance of the generator winding, the X1 plug on the "AVR" board should be removed first, and its insulation resistance should be>2M2. The insulation resistance of the already operated unit should be>0.5MQ. Check that the alarm indication and sound action on the control screen are normal. Close the battery switch, press the alarm button, and all indicator lights should flash simultaneously. The electric bell or horn should sound an alarm. Press the mute button to stop the sound. Press the alarm release button to turn off all indicator lights.

(3)?運行前,先合上控制屏上端的隔離開關(編號QS),然后將控制屏各開關置于下表所示狀態(tài):

(3) Before operation, first close the isolation switch (numbered QS) at the top of the control screen, and then place each switch on the control screen in the state shown in the table below:

(4)?燃氣機組TEM電子管理系統(tǒng)控制柜內(nèi)電源總開關置于接通位置,船形開關置于ON位置,打開主機窗口合上電源開關并按下顯示器按鈕,進入Windows2000系統(tǒng)后,雙擊12V--190機組圖標,即可進入控制程序。

(4) The main power switch in the TEM electronic management system control cabinet of the gas turbine unit is placed in the on position, and the ship shaped switch is placed in the ON position. Open the host window, close the power switch, and press the display button. After entering the Windows 2000 system, double-click the 12V-190 unit icon to enter the control program.

(5)?開機前必須將起動蓄電池的充電機電源關斷:或?qū)⒊潆姍C負極接線夾頭拆下并夾在負極線的絕緣。

(5) Before starting up, the power supply of the charging machine for the starting battery must be turned off, or the negative terminal clamp of the charging machine must be removed and clamped onto the insulation of the negative terminal wire.

(6)?將控制屏及微機柜緊急停機按鈕釋放,按下微機柜上的起動按鈕。

(6) Release the emergency stop button on the control screen and micro cabinet, and press the start button on the micro cabinet.

(7)?用手動機油泵泵油, (或用電動預供油泵泵油,蓄電池電量允許時),當油壓力表指示為0.1Mpa時停停止供油。

(7) Use a manual oil pump to pump oil (or use an electric pre supply oil pump to pump oil, when the battery power allows), and stop supplying oil when the oil pressure gauge indicates 0.1Mpa.

(8)?盤車:用人力盤轉(zhuǎn)曲軸,至少兩周,不得有卡滯或異常現(xiàn)象。

(8) Turning: Manually turn the crankshaft for at least two weeks without any jamming or abnormal phenomena.

二、發(fā)電機組的啟動及運行

2、 Startup and operation of generator set

1、機組的啟動(1)?關閉機組氣源蝶閥,踏下啟動總開關,按下啟動按鈕(3~5秒),對機組排空。

1. To start the unit (1), close the unit's air source butterfly valve, step on the main start switch, press the start button (3-5 seconds), and empty the unit.

(2)?打開氣源蝶閥,燃氣壓力最低不小于0.05 MPa,最高不大于0.3MPa。

(2) Open the gas source butterfly valve, and ensure that the minimum gas pressure is not less than 0.05 MPa and the maximum is not greater than 0.3 MPa.

(3)?踩下腳踏開關,按下啟動按鈕,發(fā)動機啟動點火運轉(zhuǎn)。起動電機連續(xù)運行不得超過10秒,若三次啟動不成功,應及時查明原因后方可再次啟動。注意:發(fā)動機啟動后,要立即釋放啟動按鈕,并踢開腳踏開關,以免損壞啟動電機。

(3) Step on the foot switch, press the start button, and the engine will start and ignite. The starting motor should not run continuously for more than 10 seconds. If it fails to start three times, the cause should be promptly identified before restarting. Attention: After starting the engine, immediately release the start button and kick off the foot switch to avoid damaging the starter motor.

(4)?發(fā)動機啟動后,使其運轉(zhuǎn)在600r/min~800r/min總速運行,進行暖機,同時觀察各儀表指示是否正常。

(4) After starting the engine, run it at a total speed of 600r/min~800r/min, warm up the engine, and observe whether the instrument readings are normal.

(5)?觀察各缸缸溫、排溫是否正常。焦爐煤氣機組:當個別缸溫超過300C時,迅速減小相應缸步進電機控制器的步數(shù),當缸溫低于150C;排溫低于300C時增加相應缸步進電機控制器的步數(shù)。

(5) Observe whether the cylinder temperature and exhaust temperature of each cylinder are normal. Coke oven gas unit: When the temperature of individual cylinders exceeds 300C, quickly reduce the number of steps of the corresponding cylinder stepper motor controller. When the cylinder temperature is below 150C, increase the number of steps of the corresponding cylinder stepper motor controller.

(6)?將怠速/額定轉(zhuǎn)換開關置于“額定”位置,使發(fā)電機組空載運行,待發(fā)動機油溫、水溫升至40C后,方可并網(wǎng)運行。

(6) Place the idle/rated switch in the "rated" position to allow the generator set to run without load. Only when the engine oil and water temperatures rise to 40C, can it be connected to the grid for operation.

(7)?調(diào)整電壓整定電位器使空載電壓為400V左右,調(diào)整轉(zhuǎn)速微調(diào)電位器使頻率為50HZ。

(7) Adjust the voltage setting potentiometer to achieve a no-load voltage of around 400V, and adjust the speed fine-tuning potentiometer to achieve a frequency of 50HZ.

(8)?按下控制屏上的儲能按鈕,給主開關儲能。

(8) Press the energy storage button on the control screen to store energy for the main switch.

2、機組并網(wǎng)運行

2. Unit grid connected operation

(1)、待發(fā)電機組運行正常后,先將發(fā)電機組的電壓、頻率調(diào)整至與電網(wǎng)大致相同時,再把同步測量開關置于“井車”位置,觀察同步表;

(1) After the generator set is running normally, first adjust the voltage and frequency of the generator set to be roughly the same as the power grid, then place the synchronous measurement switch in the "well car" position and observe the synchronous meter;

(2)、調(diào)整控制屏上的轉(zhuǎn)速微調(diào)電位器,使之與電網(wǎng)頻率相同,即同步表頻率差指示“Hz”指針處在中間略高位置:

(2) Adjust the speed adjustment potentiometer on the control screen to be the same as the grid frequency, that is, the synchronous meter frequency difference indicator "Hz" pointer is slightly higher in the middle:

(3) 、調(diào)節(jié)電壓整定電位器,使機組電壓與電網(wǎng)電壓相同,即同步表電壓差指示“V”指在中間位置。注意:反復調(diào)整發(fā)電機組,并觀察同步表相位差指示“S”指針,使其緩慢順時針旋轉(zhuǎn)。當指針旋轉(zhuǎn)接近垂直向上位置時,左手按下主開關合閘按鈕,右手斷開同步測量開關,主開關合閘并網(wǎng)發(fā)電。左手調(diào)整電壓整定電位器,將功率因數(shù)控制在滯后0.9-0.8之間,右手緩慢調(diào)整轉(zhuǎn)速微調(diào)電位器給機組加載。調(diào)整功率到合適位置(新機為60%Pe)最后將功率因數(shù)調(diào)整在0.8-0.9之間。

(3) Adjust the voltage setting potentiometer to ensure that the unit voltage is the same as the grid voltage, i.e. the synchronous meter voltage difference indicator "V" is in the middle position. Attention: Adjust the generator set repeatedly and observe the phase difference indicator "S" pointer on the synchronous meter to make it slowly rotate clockwise. When the pointer rotates close to the vertical upward position, press the main switch closing button with your left hand, disconnect the synchronous measurement switch with your right hand, and close the main switch for grid connected power generation. Adjust the voltage setting potentiometer with your left hand to control the power factor between 0.9-0.8 hysteresis, and slowly adjust the speed adjustment potentiometer with your right hand to load the unit. Adjust the power to the appropriate position (60% Se for the new machine) and finally adjust the power factor between 0.8-0.9.

(4)發(fā)電機并網(wǎng)運行中,應注意觀察電器儀表及微機柜主控畫面各項參數(shù)的指示狀況,并根據(jù)技術要求,及時修正各項參數(shù)。

(4) During the grid connected operation of the generator, attention should be paid to observing the indication status of various parameters on the electrical instruments and micro cabinet main control screen, and timely correcting various parameters according to technical requirements.

(5)機組正常運行中,每15分鐘作一次巡回檢查,觀察油溫、水溫、機油壓力、壓差、燃氣壓力及水位、油位,每兩小時對機組參數(shù)作一次記錄。三、發(fā)電機組的停機1、機組停機前,要先卸去負荷,緩慢逆時針調(diào)節(jié)轉(zhuǎn)速微調(diào)電位器,逐漸卸下負載。同時,緩慢旋轉(zhuǎn)電壓整定電位器,將功率因數(shù)控制在0.95-0.7之間,當功率降至50KW以下時,迅速按下分閘按鈕,然后使機組在額定轉(zhuǎn)速下運行幾分鐘。

(5) During normal operation of the unit, a patrol inspection is conducted every 15 minutes to observe the oil temperature, water temperature, oil pressure, pressure difference, gas pressure, water level, and oil level. The unit parameters are recorded every two hours. 3、 Shutdown of Generator Set 1. Before shutting down the generator set, the load should be removed first, and the speed adjustment potentiometer should be slowly adjusted counterclockwise to gradually remove the load. At the same time, slowly rotate the voltage setting potentiometer to control the power factor between 0.95-0.7. When the power drops below 50KW, quickly press the disconnect button and let the unit run at rated speed for a few minutes.

2、將轉(zhuǎn)速轉(zhuǎn)換開關撥至“怠速”位置,使機組轉(zhuǎn)速降至總速運行。

2. Turn the speed conversion switch to the "idle" position to reduce the unit speed to the total speed for operation.

3、待機組油溫、水溫降至40C以下時,關斷機組氣源蝶閥,將電磁閥開關、電調(diào)開關置于斷開位置,并按下微機柜緊急停機按鈕,機組停止。

3. When the oil and water temperature of the standby unit drops below 40C, turn off the air source butterfly valve of the unit, place the solenoid valve switch and electric control switch in the off position, and press the emergency stop button of the micro cabinet to stop the unit.

4、較長時間停機或機組檢修時,應關閉外循環(huán)冷卻水進口閥門和燃氣進口閥門。若環(huán)境溫度低于5C時,還應將機組內(nèi)循環(huán)冷卻水放凈,并將水泵及外循環(huán)冷卻水管線上的放水堵打開將水放凈,必要時應用空氣壓縮機吹掃管線。

4. When the unit is shut down for a long time or undergoing maintenance, the external circulation cooling water inlet valve and gas inlet valve should be closed. If the ambient temperature is below 5C, the circulating cooling water inside the unit should be drained completely, and the drain plugs on the water pump and external circulating cooling water pipeline should be opened to drain the water. If necessary, an air compressor should be used to blow the pipeline.

5、手動盤車至少5圈,同時有手動預供油泵泵油0.01Mpa。

5. Manual turning should be done at least 5 times, and there should be a manual pre supply oil pump that pumps oil at 0.01Mpa.

四、發(fā)電機組故障停機的處理

4、 Handling of generator set shutdown due to malfunction

1、當發(fā)電機組因超速、過電流、逆功率、水溫、油溫高及油壓低故障,引起突然停機時。應關斷氣源,查明故障原因并妥善處理后方可開機。2、當遇有緊急情況,可按下“緊急停車”按鈕,使機組停機。注意:突然緊急停機后,一定要用人力盤車,盤轉(zhuǎn)曲軸至少5圈,同時用手動預供油泵泵油,待機組水溫、油溫降低后,進行檢查處理,并向有關部門或領導匯報。

1. When the generator set suddenly shuts down due to overspeed, overcurrent, reverse power, high water temperature, high oil temperature, and low oil pressure faults. The gas source should be turned off, the cause of the malfunction should be identified and properly handled before starting up. 2. In case of emergency, the "emergency stop" button can be pressed to shut down the unit. Attention: After a sudden emergency stop, it is necessary to manually turn the crankshaft at least 5 times and use a manual pre supply oil pump to pump oil. After the water temperature and oil temperature of the standby group decrease, check and handle it, and report to the relevant department or leader.

檢查燃氣發(fā)電機組的進氣系統(tǒng),可按以下步驟進行:

To check the intake system of the gas generator set, the following steps can be taken:

1.外觀檢查

1. Appearance inspection

· 檢查進氣管道、濾清器、連接法蘭等部件是否有破損、裂縫或松動,確保所有連接部位密封良好,無漏氣現(xiàn)象。

·Check for any damage, cracks, or looseness in the intake pipes, filters, connecting flanges, and other components to ensure that all connecting parts are well sealed and free of air leaks.

· 查看空氣濾清器是否堵塞或臟污,若濾清器阻力增大,可能導致進氣不暢,需及時清理或更換。

·Check if the air filter is clogged or dirty. If the filter resistance increases, it may cause poor air intake and needs to be cleaned or replaced in a timely manner.

2.壓力檢查

2. Pressure check

· 檢查進氣系統(tǒng)的壓力傳感器,確保其正常工作,顯示的壓力值應在機組規(guī)定的范圍內(nèi)。

·Check the pressure sensor of the intake system to ensure its normal operation, and the displayed pressure value should be within the range specified by the unit.

· 若配備壓差傳感器,監(jiān)測濾清器前后壓差,當壓差超過設定值時,可能表示濾清器堵塞或系統(tǒng)存在故障,需進一步排查。

·If equipped with a differential pressure sensor to monitor the pressure difference before and after the filter, when the pressure difference exceeds the set value, it may indicate that the filter is clogged or there is a system malfunction, and further investigation is needed.

3.進氣閥門檢查

3. Inspection of intake valve

· 檢查進氣閥門的開閉狀態(tài)是否正常,閥門應能靈活開啟和關閉,無卡滯或泄漏。

·Check if the opening and closing status of the intake valve is normal. The valve should be able to open and close flexibly without any jamming or leakage.

· 確認閥門的控制機構(如電動閥、氣動閥)工作正常,能準確響應機組的運行指令。

·Confirm that the control mechanism of the valve (such as electric valve, pneumatic valve) is working properly and can accurately respond to the operating instructions of the unit.

4.進氣控制系統(tǒng)檢查

4. Inspection of intake control system

· 檢查進氣控制系統(tǒng)的電氣連接是否牢固,有無松動、腐蝕或損壞的跡象。

·Check if the electrical connections of the intake control system are secure and if there are any signs of looseness, corrosion, or damage.

· 若機組配備進氣調(diào)節(jié)裝置(如節(jié)氣門、進氣旁通閥等),檢查其動作是否靈活,調(diào)節(jié)功能是否正常。

·If the unit is equipped with an intake control device (such as throttle valve, intake bypass valve, etc.), check whether its action is flexible and whether the adjustment function is normal.

5.防喘振系統(tǒng)檢查

5. Inspection of anti surge system

· 對于配備防喘振裝置的機組,檢查防喘振閥的開閉狀態(tài)和動作是否正常,確保其能在機組運行過程中有效防止喘振現(xiàn)象的發(fā)生。

·For units equipped with anti surge devices, check whether the opening and closing status and action of the anti surge valve are normal, to ensure that it can effectively prevent the occurrence of surge phenomenon during the operation of the unit.

· 檢查防喘振系統(tǒng)的控制邏輯和傳感器信號是否正常,確保系統(tǒng)能根據(jù)機組的運行工況自動調(diào)整防喘振閥的開度。

·Check whether the control logic and sensor signals of the anti surge system are normal, and ensure that the system can automatically adjust the opening of the anti surge valve according to the operating conditions of the unit.

6.清潔與維護

6. Cleaning and maintenance

· 定期清理進氣系統(tǒng)的灰塵、雜物和積碳,保持進氣通道的暢通。

·Regularly clean the dust, debris, and carbon deposits in the intake system to keep the intake passage unobstructed.

· 根據(jù)機組的運行環(huán)境和使用頻率,定期更換空氣濾清器,以保證進氣質(zhì)量。通過以上檢查,可及時發(fā)現(xiàn)進氣系統(tǒng)的問題并進行處理,確保燃氣發(fā)電機組的正常運行。若發(fā)現(xiàn)問題,應及時聯(lián)系專業(yè)維修人員進行檢修。

·Regularly replace the air filter according to the operating environment and frequency of use of the unit to ensure intake quality. Through the above inspections, problems with the intake system can be promptly identified and addressed to ensure the normal operation of the gas generator set. If any problems are found, professional maintenance personnel should be contacted in a timely manner for repair.

本文由 燃氣發(fā)電機組 友情奉獻.更多有關的知識請點擊 http://www.ttyule.net.cn/ 真誠的態(tài)度.為您提供為全面的服務.更多有關的知識我們將會陸續(xù)向大家奉獻.敬請期待.

This article is a friendly contribution from a gas generator set For more related knowledge, please click http://www.ttyule.net.cn/ Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.

在線咨詢

在線咨詢 官方二維碼

官方二維碼

當前位置:

當前位置: 2025.11.15

2025.11.15