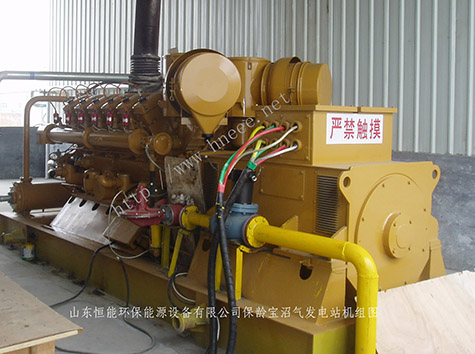

焦化氣發(fā)電機組:焦化廠的環(huán)保指標(biāo)有哪些?

中國焦化企業(yè)眾多,焦化企業(yè)存在工藝復(fù)雜,產(chǎn)生污染物種類較多的特點,環(huán)境監(jiān)察人員必須對焦化企業(yè)產(chǎn)污環(huán)節(jié)、治理措施等有全面的了解,在環(huán)境監(jiān)察工作中才能做到心中有數(shù)、執(zhí)法到位。本文對焦化企業(yè)排污點位、應(yīng)采取的治理措施及執(zhí)行環(huán)境標(biāo)準(zhǔn)等進(jìn)行了簡要的介紹,并對焦化行業(yè)環(huán)境監(jiān)察應(yīng)注意的點位進(jìn)行了逐一的分析。

There are numerous coking enterprises in China, which have complex processes and produce a variety of pollutants. Environmental monitoring personnel must have a comprehensive understanding of the pollution production processes and control measures of coking enterprises in order to have a clear understanding and effective law enforcement in environmental monitoring work. This article briefly introduces the pollution discharge points of coking enterprises, the governance measures that should be taken, and the implementation of environmental standards. It also analyzes the points that should be paid attention to in environmental supervision of the coking industry one by one.

焦化生產(chǎn)工藝

Coking production process

焦化生產(chǎn)大體分兩個工段:備煤、煉焦工段、化產(chǎn)回收及焦化廢水生化處理工段。煉焦工段是煤經(jīng)加溫蒸餾變成焦炭的過程,化產(chǎn)回收工段是對煤氣中化學(xué)產(chǎn)品的回收過程,一般主要有冷鼓、脫硫、硫銨、洗脫苯等工段。

Coking production is generally divided into two sections: coal preparation, coking section, and chemical product recovery and coking wastewater biochemical treatment section. The coking section is the process of coal being heated and distilled into coke, while the chemical recovery section is the process of recovering chemical products from coal gas, generally including cold drum, desulfurization, ammonium sulfate, and benzene washing sections.

焦化生產(chǎn)過程污染源分析、治理措施及監(jiān)察要點

Analysis of Pollution Sources, Control Measures and Supervision Points in Coking Production Process

2.1?廢氣部分 (1)裝煤、煉焦、出焦。

2.1? Waste gas section (1) includes coal loading, coking, and coke discharge.

①裝煤時,煤中水分蒸發(fā)和揮發(fā)份迅速產(chǎn)生,炭化室壓力突然上升,廢氣逸散。主要污染物為BaP、顆粒物、H2S、NH3、酚等污染物質(zhì)。 需配套建設(shè)裝煤消煙除塵設(shè)施,如:爐頂燃燒+噴淋處理、側(cè)吸導(dǎo)管、二合一地面站等。

① When loading coal, the water in the coal evaporates and volatile matter is rapidly produced, causing a sudden increase in pressure in the carbonization chamber and the release of exhaust gas. The main pollutants are BaP, particulate matter H2S、NH3、 Phenol and other pollutants. Supporting facilities for coal loading, smoke reduction, and dust removal need to be constructed, such as furnace top combustion+spray treatment, side suction ducts, and two in one ground stations.

②爐頂廢氣及爐門泄露廢氣。 裝煤孔蓋、上升管蓋、上升管與爐門頂連接處、橋管液封連接不嚴(yán),荒煤氣從縫隙中泄露,焦?fàn)t爐頂散落煤,受熱分解也產(chǎn)生煙氣。煉焦過程中爐門刀邊爐框鏡面不嚴(yán)密處產(chǎn)生的泄露廢氣。主要污染物為顆粒物、苯、BaP、SO2、CO、NO2、H2S、NH3、酚類等,成分復(fù)雜且具有較大的毒害性。 需采用水封式上升管,特制泥封,及時清理爐頂、爐門爐框等。

② Furnace top exhaust gas and furnace door leakage exhaust gas. The coal loading hole cover, rising pipe cover, connection between the rising pipe and the furnace door top, and the liquid seal connection of the bridge pipe are not tightly sealed, causing the leakage of raw gas from the gaps, scattering coal on the top of the coke oven, and generating flue gas through thermal decomposition. The leakage of exhaust gas generated at the imperfect mirror surface of the furnace door blade and frame during the coking process. The main pollutants are particulate matter, benzene BaP、SO2、CO、NO2、H2S、NH3、 Phenols and other compounds are complex in composition and have significant toxicity. It is necessary to use a water sealed riser, specially sealed with mud, and clean the furnace top, door, and frame in a timely manner.

③推焦煙氣。 成熟焦炭經(jīng)推焦車、攔焦車從炭化室推出進(jìn)入熄焦車,高溫?zé)煔鈴膶?dǎo)焦槽頂部等處排出。主要污染物為顆粒物、苯、BaP、SO2、CO、NO2、H2S、NH3、等。 需配套建設(shè)攔焦車集塵罩及地面除塵站。

③ Pushing coke smoke. Mature coke is pushed out of the coking chamber by the pushing and blocking cars and enters the quenching car. High temperature flue gas is discharged from the top of the coke guide groove and other places. The main pollutants are particulate matter, benzene BaP、SO2、CO、NO2、H2S、NH3、 Wait. It is necessary to construct a dust collection hood and ground dust removal station for the coke blocking vehicle.

④熄焦塔排氣。 熾熱焦炭與熄焦水接觸,產(chǎn)生大量水汽,攜帶污染物排放。主要污染物為焦粉、BaP、CO、H2S、酚類、氰化物等。 需設(shè)置木質(zhì)折流板除塵。

④ Exhaust gas from the quenching tower. Hot coke comes into contact with quenching water, producing a large amount of water vapor and carrying pollutants for discharge. The main pollutants are coke powder BaP、CO、H2S、 Phenols, cyanides, etc. Wooden baffle dust removal is required.

⑤焦?fàn)t煙囪排氣。 焦?fàn)t加熱燃燒室燃燒煤氣產(chǎn)生的廢氣。主要污染物為煙塵、SO2、NOx等。 需燃用凈化后的焦?fàn)t煤氣。

⑤ Coke oven chimney exhaust. The exhaust gas generated by the combustion of coal gas in the heating combustion chamber of a coke oven. The main pollutants are smoke, SO2, NOx, etc. Purified coke oven gas needs to be used.

⑥篩儲焦工序。 熄焦后焦炭在破碎、篩分、儲存時產(chǎn)生的粉塵。 需設(shè)置篩儲焦樓,在篩焦樓及轉(zhuǎn)運站等處設(shè)置除塵設(shè)施,焦炭堆場設(shè)置擋風(fēng)抑塵網(wǎng)。

⑥ Screening and storage coke process. Dust generated during the crushing, screening, and storage of quenched coke. It is necessary to set up a coke screening and storage building, dust removal facilities at the coke screening building and transfer station, and wind and dust suppression nets at the coke yard.

⑦事故狀態(tài)下焦?fàn)t放散荒煤氣。 需設(shè)置雙回路電源、煤氣自動點火裝置。最大限度減小停電事故的發(fā)生,即使發(fā)生,煤氣自動點火裝置將荒煤氣點火燃燒,可減輕事故狀態(tài)時對環(huán)境的污染。 監(jiān)察要點:精煤堆場防風(fēng)抑塵網(wǎng)、輸煤走廊密閉、裝煤出焦消煙除塵設(shè)施運行情況、爐門封閉情況、熄焦塔木質(zhì)折流板、篩焦粉塵除塵設(shè)施、雙回路電源、煤氣自動點火裝置、查看運行記錄及在線監(jiān)測SO2等數(shù)據(jù)。

⑦ During an accident, the coke oven released waste gas. Dual circuit power supply and automatic gas ignition device need to be installed. Minimize the occurrence of power outages to the greatest extent possible. Even if they occur, the automatic gas ignition device will ignite and burn the depleted gas, which can reduce environmental pollution during accident situations. Key monitoring points: windproof and dust suppression network in the clean coal yard, closed coal transportation corridor, operation of coal loading and coking smoke and dust removal facilities, closure of furnace doors, wooden baffle plates in the quenching tower, dust removal facilities for screening coke, dual circuit power supply, automatic gas ignition device, viewing of operation records, and online monitoring of SO2 and other data.

(2)煤氣凈化。

(2) Gas purification.

①冷凝鼓風(fēng)工段,機械化焦油氨水澄清槽氨水分離過程中產(chǎn)生的廢氣,焦油貯槽、循環(huán)氨水中間槽、成品苯貯槽揮發(fā)逸散的廢氣。主要污染物為HCN、BaP、NH3、H2S等。 需統(tǒng)一收集送排氣洗凈塔洗凈后排放。

① The exhaust gas generated during the separation of ammonia water in the mechanized tar ammonia water clarification tank, as well as the exhaust gas emitted from the volatilization of tar storage tank, circulating ammonia water intermediate tank, and finished benzene storage tank in the condensation and blowing section. The main pollutants are HCN, BaP, NH3, H2S, etc. It is necessary to collect and discharge the exhaust gas after being cleaned by the cleaning tower.

②脫硫再生塔排氣。 煤氣脫硫產(chǎn)生的富液送再生塔再生時有部分尾氣從塔頂排出。主要污染物為HCN、NH3、H2S等。 需統(tǒng)一收集送排氣洗凈塔洗凈后排放。

② Exhaust gas from desulfurization regeneration tower. When the rich liquid produced by gas desulfurization is sent to the regeneration tower for regeneration, some of the tail gas is discharged from the top of the tower. The main pollutants are HCN, NH3, H2S, etc. It is necessary to collect and discharge the exhaust gas after being cleaned by the cleaning tower.

③煤氣中的硫化物。 一般采用濕法脫硫,減少煤氣作為燃料燃燒時SO2等污染物的排放量。脫硫工段包括煤氣脫硫、脫硫液再生、硫回收三部分。脫硫的主要任務(wù)是將煤氣中的硫化氫脫至≤200mg/m3,并回收硫磺。

③ Sulfides in coal gas. Generally, wet desulfurization is used to reduce the emissions of pollutants such as SO2 during the combustion of coal gas as fuel. The desulfurization section includes three parts: gas desulfurization, desulfurization liquid regeneration, and sulfur recovery. The main task of desulfurization is to remove hydrogen sulfide from gas to ≤ 200mg/m3 and recover sulfur.

④煤氣中的氨。 一般采用硫銨工段去除,用硫酸洗去煤氣中的氨并生產(chǎn)硫銨,將煤氣中的氨含量脫至500mg/m3以下。將生成的硫銨干燥成硫銨成品,同時將冷鼓來的剩余氨水蒸氨。

④ Ammonia in gas. Generally, the ammonium sulfate section is used for removal, and sulfuric acid is used to wash away the ammonia in the gas and produce ammonium sulfate, reducing the ammonia content in the gas to below 500mg/m3. Dry the generated ammonium sulfate into finished ammonium sulfate products, while steaming the remaining ammonia water from the cold drum.

⑤煤氣中的苯。 洗脫苯工段去除,包括終冷、洗苯、脫苯三部分。終冷主要是將硫銨工段來的煤氣冷卻到25℃~27℃,洗苯是用洗油洗去煤氣中的苯,脫苯是將洗苯后的含苯富油脫苯,生產(chǎn)輕苯、重苯出售,脫苯后的貧油返回洗苯塔循環(huán)使用。

⑤ Benzene in gas. The benzene washing section includes three parts: final cooling, benzene washing, and benzene removal. Final cooling is mainly used to cool the gas from the ammonium sulfate section to 25 ℃~27 ℃. Benzene washing is to wash away the benzene in the gas with washing oil, and benzene removal is to remove the benzene from the rich oil containing benzene after washing, producing light benzene and heavy benzene for sale. The lean oil after benzene removal is returned to the benzene washing tower for recycling.

⑥硫銨工段干燥系統(tǒng)排出的含NH3等污染物的尾氣,生產(chǎn)系統(tǒng)排放的硫銨粉塵。 需設(shè)置旋風(fēng)除塵器和水浴除塵器兩級除塵。

⑥ The tail gas containing NH3 and other pollutants emitted from the drying system of the ammonium sulfate section, and the ammonium sulfate dust emitted from the production system. Two levels of dust removal, cyclone dust collector and water bath dust collector, need to be installed.

⑦粗苯管式爐。 需燃用冷凝、脫氨、脫硫、脫苯后的焦?fàn)t煤氣。 監(jiān)察要點:排氣洗凈塔以及廢氣收集管路、硫銨工段旋風(fēng)除塵器和水浴除塵器運行情況。

⑦ Crude benzene tube furnace. Coke oven gas needs to be used after condensation, deamination, desulfurization, and benzene removal. Monitoring points: Operation status of exhaust cleaning tower, exhaust gas collection pipeline, cyclone dust collector and water bath dust collector in the ammonium sulfate section.

(3)剩余煤氣利用(煤氣發(fā)電、制甲醇、綜合利用等)。 煤氣發(fā)電鍋爐燃用冷凝、脫氨、脫硫、脫苯后的焦?fàn)t煤氣。 監(jiān)察要點:各工段是否均使用凈煤氣。

(3) Utilization of surplus gas (gas power generation, methanol production, comprehensive utilization, etc.). Gas fired power boilers use coke oven gas that has been condensed, deammoniated, desulfurized, and dehenzolized. Key monitoring points: Whether all sections use clean coal gas.

2.2?廢水部分 焦化生產(chǎn)廢水分為生產(chǎn)凈廢水和生產(chǎn)污水兩部分。生產(chǎn)凈廢水主要為間接冷卻水、軟水站及鍋爐排水,為高濃度鹽水,水質(zhì)較為簡單。生產(chǎn)污水來源于與物料直接接觸水。

2.2? The coking production wastewater is divided into two parts: production clean wastewater and production wastewater. The production clean wastewater mainly consists of indirect cooling water, soft water station and boiler drainage, which are high concentration saltwater with relatively simple water quality. Production wastewater comes from water that comes into direct contact with materials.

(1)熄焦廢水。 含有焦塵以及微量的揮發(fā)酚、氰化物等污染物。 需經(jīng)熄焦沉淀池沉淀后,除去含有的焦粉后循化使用。

(1) Coke extinguishing wastewater. Containing coke dust and trace amounts of volatile phenols, cyanides, and other pollutants. After settling in the quenching sedimentation tank, remove the contained coke powder and use it gradually.

(2)剩余氨水。 冷凝鼓風(fēng)工段機械化焦油氨水澄清槽分離出來的剩余氨水,經(jīng)蒸氨去除廢水中部分氰化物、氨和H2S后送污水處理站處理。蒸出的氨氣冷凝后分別進(jìn)入脫硫工序作為脫硫的堿源,蒸氨后的廢水送污水處理站處理。蒸氨廢水氨氮濃度控制在200mg/L以下,為保證蒸氨廢水氨氮穩(wěn)定控制,需設(shè)置備用蒸氨塔和氨水事故槽。

(2) Remaining ammonia water. The residual ammonia water separated from the mechanized tar ammonia water clarification tank in the condensation and blowing section is sent to the sewage treatment plant for treatment after removing some cyanide, ammonia, and H2S from the wastewater through ammonia distillation. The evaporated ammonia gas is condensed and then enters the desulfurization process as the alkali source for desulfurization. The wastewater after ammonia evaporation is sent to the sewage treatment station for treatment. The concentration of ammonia nitrogen in the steam ammonia wastewater should be controlled below 200mg/L. To ensure stable control of ammonia nitrogen in the steam ammonia wastewater, backup steam ammonia towers and ammonia emergency tanks need to be set up.

(3)煤氣冷凝水、粗苯及各貯槽分離水等工藝廢水。 煤氣凈化系統(tǒng)各環(huán)節(jié)設(shè)置相應(yīng)的圍堰、地下放空槽及集液坑等收集放空廢液、廢水、高濃度沖洗廢水等,視水質(zhì)情況送機械化氨水澄清槽或排至污水處理站處理。 煤氣冷凝液、粗苯及各貯槽分離水等工藝廢水,送入焦油氨水分離槽分離后,隨剩余氨水一同去蒸氨塔。 各貯槽放散氣洗滌廢水、硫銨尾氣凈化產(chǎn)生的廢水,均進(jìn)入污水處理站處理。

(3) Process wastewater such as gas condensate, crude benzene, and separation water from various storage tanks. Corresponding cofferdams, underground venting tanks, and collection pits are set up at each stage of the gas purification system to collect venting waste liquid, wastewater, high concentration flushing wastewater, etc. Depending on the water quality, they are sent to mechanized ammonia water clarification tanks or discharged to sewage treatment plants for treatment. The process wastewater such as gas condensate, crude benzene, and separation water from various storage tanks are sent to the tar ammonia water separation tank for separation, and then sent to the ammonia distillation tower together with the remaining ammonia water. The wastewater discharged from each storage tank for gas washing and the wastewater generated from ammonium sulfate tail gas purification are all sent to the sewage treatment plant for treatment.

(4)軟水站、鍋爐排水及循環(huán)冷卻水系統(tǒng)凈排水。 軟水站廢水采樣中和池進(jìn)行酸堿中和后,與鍋爐排水及循環(huán)冷卻水系統(tǒng)排污水一起,回用或送污水處理站做稀釋水。

(4) Soft water station, boiler drainage, and clean drainage of circulating cooling water system. After acid-base neutralization in the wastewater sampling and neutralization tank of the soft water station, it is reused or sent to the sewage treatment station as dilution water together with the boiler drainage and circulating cooling water system sewage.

(5)生活污水、化驗水、雨水、地坪沖洗水。 送污水處理站處理。

(5) Domestic sewage, laboratory water, rainwater, floor flushing water. Send it to the sewage treatment plant for treatment.

(6)污水處理站出水。 處理合格后全部作為熄焦的補充水。需設(shè)置調(diào)節(jié)池和事故排放池。 監(jiān)察要點:熄焦沉淀池、備用蒸氨塔和氨水事故槽、污水處理站工藝、能力、調(diào)節(jié)池和事故排放池、查看運行記錄及出水水質(zhì)在線監(jiān)測COD等數(shù)據(jù)。

(6) Wastewater treatment plant effluent. After passing the treatment, all of it will be used as supplementary water for quenching coke. A regulating pool and an accident discharge pool need to be set up. Key monitoring points: coke quenching sedimentation tank, backup ammonia distillation tower and ammonia accident tank, sewage treatment plant process, capacity, regulating tank and accident discharge tank, viewing operation records and online monitoring of effluent quality COD and other data.

2.3?固廢部分

2.3? Solid waste part

(1)焦油渣。 冷鼓工段機械化氨水澄清槽中分離出的焦油渣,含有煤焦油瀝青、酚油、萘油、蒽油等成分,屬危險固廢。現(xiàn)階段要求摻煤煉焦。

(1) Tar residue. The tar residue separated from the mechanized ammonia water clarification tank in the cold drum section contains components such as coal tar pitch, phenol oil, naphthalene oil, anthracene oil, etc., and is classified as hazardous solid waste. At present, coal blending is required for coking.

(2)脫硫廢液。 是為了避免脫硫及再生過程鹽分積累,定期抽出的部分廢液,屬危險固廢。現(xiàn)階段要求摻煤煉焦。

(2) Flue gas desulfurization waste liquid. It is a hazardous solid waste that is periodically extracted to avoid salt accumulation during desulfurization and regeneration processes. At present, coal blending is required for coking.

(3)粗苯再生器脫苯殘渣。 洗脫苯過程中洗油再生時,再生器排出的脫苯殘渣,屬危險固廢。現(xiàn)階段要求摻煤煉焦。

(3) Crude benzene regenerator removes benzene residue. During the process of washing benzene and regenerating the washing oil, the benzene removal residue discharged from the regenerator is classified as hazardous solid waste. At present, coal blending is required for coking.

(4)瀝青渣。 蒸氨塔產(chǎn)生的瀝青渣,屬危險固廢。現(xiàn)階段要求摻煤煉焦。

(4) Asphalt residue. The asphalt residue produced by the ammonia distillation tower is classified as hazardous solid waste. At present, coal blending is required for coking.

(5)酸焦油。 硫銨工段產(chǎn)生,屬危險固廢。現(xiàn)要求階段摻煤煉焦。

(5) Acid tar. The ammonium sulfate section generates hazardous solid waste. At present, coal blending is required for coking.

(6)生化污泥及廢油渣。 生化污水處理站產(chǎn)生,除油產(chǎn)生的廢油渣和生化產(chǎn)生的剩余污泥,屬危險固廢。現(xiàn)階段要求摻煤煉焦。

(6) Biochemical sludge and waste oil residue. The waste oil residue and residual sludge generated by the biochemical wastewater treatment plant are classified as hazardous solid waste. At present, coal blending is required for coking.

(7)除塵灰。 各除塵系統(tǒng)回收的粉塵現(xiàn)階段均要求摻煤煉焦

(7) Dust removal. At present, the dust collected by each dust removal system requires coal blending for coking

(8)生活垃圾。 要求定期送政府指定的垃圾填埋場處理。 監(jiān)察要點:焦油渣、脫硫廢液、脫苯殘渣、瀝青渣、酸焦油、污水處理站廢油渣、剩余污泥等有無專用堆存場所,地面防滲情況,生活垃圾收集、填埋情況。

(8) Household garbage. Require regular disposal at government designated landfill sites. Key monitoring points: Whether there are dedicated storage areas for tar residue, desulfurization waste liquid, benzene removal residue, asphalt residue, acid tar, waste oil residue from sewage treatment plants, residual sludge, etc., the anti-seepage situation on the ground, and the collection and landfill of household waste.

2.4?噪聲污染源分析

2.4? Analysis of Noise Pollution Sources

主要為各種風(fēng)機等產(chǎn)噪生產(chǎn)設(shè)備,需采用加裝消音器、基礎(chǔ)減震、車間密閉等措施。

Mainly for various noise generating production equipment such as fans, measures such as installing mufflers, basic shock absorbers, and workshop sealing are required.

監(jiān)察要點:消音器、基礎(chǔ)減震、車間密閉措施。

Key monitoring points: Silencers, foundation shock absorbers, and workshop sealing measures.

執(zhí)行環(huán)境標(biāo)準(zhǔn)

Implement environmental standards

3.1 廢氣排放標(biāo)準(zhǔn)

3.1 Exhaust emission standards

(1)煉焦?fàn)t爐頂無組織污染物排放執(zhí)行《煉焦?fàn)t大氣污染物排放標(biāo)準(zhǔn)》(GB16171-1996)。標(biāo)準(zhǔn)中規(guī)定,位于GB3095中一類區(qū)執(zhí)行一級標(biāo)準(zhǔn),二類區(qū)執(zhí)行二級標(biāo)準(zhǔn),三類區(qū)執(zhí)行三級標(biāo)準(zhǔn)。禁止在一類區(qū)新建、擴建機械化煉焦?fàn)t和非機械化煉焦?fàn)t,改建項目不得增加排污量。

(1) The unorganized pollutant emissions from the top of the coke oven shall comply with the "Emission Standards for Air Pollutants from Coking Furnaces" (GB16171-1996). According to the standard, Class I areas in GB3095 shall comply with the first level standard, Class II areas shall comply with the second level standard, and Class III areas shall comply with the third level standard. It is prohibited to build or expand mechanized and non mechanized coke ovens in Class I areas, and renovation projects shall not increase the amount of pollutants discharged.

(2)顆粒物、SO2、NOx、BaP、酚類、氰化氫、苯等焦化有組織廢氣排放及廠界無組織排放監(jiān)控濃度執(zhí)行《大氣污染物綜合排放標(biāo)準(zhǔn)》(GB16297-1996)。 NH3、H2S有組織污染

(2) Particulate matter SO2、NOx、BaP、 The monitoring concentration of organized waste gas emissions and unorganized emissions from coking plants such as phenols, hydrogen cyanide, and benzene shall comply with the Comprehensive Emission Standards for Air Pollutants (GB16297-1996). Organized pollution of NH3 and H2S

源及廠界無組織排放執(zhí)行《惡臭污染物排放標(biāo)準(zhǔn)》(GB14554-93)。

The unorganized emissions at the source and factory boundaries shall comply with the "Emission Standards for Odor Pollutants" (GB14554-93).

(3)中小型焦化廠配置的鍋爐一般采用凈化后焦?fàn)t煤氣為燃料,相應(yīng)鍋爐大氣污染物排放執(zhí)行《鍋爐大氣污染物排放標(biāo)準(zhǔn)》(GB13271-2001)中的燃?xì)忮仩t排放標(biāo)準(zhǔn)。

(3) The boilers equipped in small and medium-sized coking plants generally use purified coke oven gas as fuel, and the corresponding boiler air pollutant emissions comply with the gas boiler emission standards in the "Boiler Air Pollutant Emission Standards" (GB13271-2001).

3.2?廢水排放標(biāo)準(zhǔn)

3.2? Wastewater discharge standards

焦化廢水排放執(zhí)行《鋼鐵工業(yè)水污染物排放標(biāo)準(zhǔn)》(GB13456-92)。在《鋼鐵工業(yè)水污染物排放標(biāo)準(zhǔn)》中未規(guī)定的污染物排放標(biāo)準(zhǔn),執(zhí)行《污水綜合排放標(biāo)準(zhǔn)》(GB8978-96)。 3.3?其它排放標(biāo)準(zhǔn) 廠界噪聲排放執(zhí)行《工業(yè)企業(yè)廠界環(huán)境噪聲排放標(biāo)準(zhǔn)》(GB12348-2008)。

The discharge of coking wastewater shall comply with the "Emission Standards for Water Pollutants in the Iron and Steel Industry" (GB13456-92). The pollutant discharge standards not specified in the "Steel Industry Water Pollutant Discharge Standards" shall be implemented in accordance with the "Comprehensive Wastewater Discharge Standards" (GB8978-96). 3.3? Other emission standards for factory boundary noise emissions shall comply with the "Emission Standards for Industrial Enterprise Boundary Environmental Noise" (GB12348-2008).

3.4?固體廢物 一般工業(yè)固體廢物執(zhí)行《一般工業(yè)固體廢物儲存、處置場污染控制標(biāo)準(zhǔn)》(GB18599-2001)。危險廢物貯存執(zhí)行《危險廢物貯存污染控制標(biāo)準(zhǔn)》(GB18597-2001)。

3.4? Solid waste: General industrial solid waste shall comply with the Pollution Control Standards for Storage and Disposal Sites of General Industrial Solid Waste (GB18599-2001). The storage of hazardous waste shall comply with the Pollution Control Standards for Hazardous Waste Storage (GB18597-2001).

實際工作中特別要注意的是:如環(huán)境影響報告書、環(huán)評批復(fù)對企業(yè)執(zhí)行環(huán)境標(biāo)準(zhǔn)有明確要求的,以環(huán)評批復(fù)執(zhí)行標(biāo)準(zhǔn)為準(zhǔn)。

In practical work, it is particularly important to note that if there are clear requirements for enterprises to implement environmental standards in environmental impact assessment reports and environmental impact assessment approvals, the environmental impact assessment approval execution standards shall prevail.

總之,焦化企業(yè)污染源點多面廣,環(huán)境監(jiān)察難度較大,因此需要監(jiān)察人員不斷學(xué)習(xí)研究,以認(rèn)真負(fù)責(zé)的態(tài)度開展環(huán)境監(jiān)察工作,發(fā)現(xiàn)并解決企業(yè)存在的環(huán)境問題。

In short, coking enterprises have multiple sources of pollution, making environmental monitoring difficult. Therefore, it is necessary for monitoring personnel to continuously learn and research, carry out environmental monitoring work with a serious and responsible attitude, and discover and solve environmental problems existing in the enterprise.

本文由 焦化氣發(fā)電機組 友情奉獻(xiàn).更多有關(guān)的知識請點擊 http://www.ttyule.net.cn/ 真誠的態(tài)度.為您提供為全面的服務(wù).更多有關(guān)的知識我們將會陸續(xù)向大家奉獻(xiàn).敬請期待

This article is a friendly contribution from a coking gas generator set For more related knowledge, please click http://www.ttyule.net.cn/ Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Stay tuned

在線咨詢

在線咨詢 官方二維碼

官方二維碼

當(dāng)前位置:

當(dāng)前位置: 2025.11.20

2025.11.20